AQUADRIL® high performance water-based mud system is designed using innovative polymers with minimal dosage to drill in high temperature reservoir as an environmentally alternative to traditional sulfonated black powder additives or oil-based mud. This enables achievable fluid solutions to address the technical challenges brought by ultra-high temperature, ultra-high pressure and ultra-deep wells, and meet the current increasingly demanded requirements for operations at depths of over 10,000 meters. Not same to dispersed system, AQUADRIL® contains no black powder additives, is polymer-based portfolio with extreme-low solids content to achieve optimum rheology properties and low filtration loss from 300°F to 465°F without any high-temperature gelation or barite sag issues.

AQUADRIL® HTWBM is compatible to any brines including monovalent brines, divalent brines and formate brines, contributing its application to higher density with less solids content.

KEY PRODUCTS

AQUADRIL ® HTWBM delivers superb a high degree of thermal stability under both dynamic and long-term static HPHT conditions. This can be achieved through the combination of below core additives including AQUATEMPTM (HT FLA, AAM - AMPS copolymer), AQUATROL® (HT FLA, AM - AMPS copolymer), AQUAVIS® (HT viscosifier), AQUAVIS® L (LSRV) and AQUATHIN® (HT thinner, SSMA).

AQUATEMPTM - Synthetic copolymer of acrylamide-AMPS. Effective HPHT filtration control agent at low concentrations, white free-flowing powder.

• Stable at temperature above 350°F

• Improves drilling fluid suspension properties and mitigate barite sag issue under extreme HT environment

• Multifunctional, high temperature additive provides filtration control, inhibition and viscosity

• Inhibits hydratable and sloughing shale, maintain the integrity of cuttings

AQUATROL® - Synthetic terpolymer filtration control additive. Readily dispersible, white free-flowing powder. Displays excellent synergism with other common fluids additives.

• Thermal stability over 450°F (230°C)

• Compatible with other common mud additives

• Low filtration and good cake erodibility

• Tolerant to salts and divalent metal ions

• Environmentally safe

AQUAVIS® - Synthetic water-soluble polymer, off-white free-flowing powder. Viscosify fresh and brine-based drilling fluids with higher thermal stability

• Higher thermal stability above 300°F

• Provides elevated low shear rate viscosity with minimal plastic viscosity

• Hydrates rapidly in most aqueous systems

AQUAVIS® L - Slightly crosslinked synthetic polymer, white viscous liquid. Provides superior performance by increasing low-end rheology.

• Thermal stability over 400°F

• Excellent rheological profile with elevated low-end readings essential for hole cleaning

• Impacts thixotropy

• Prevents settling

AQUATHIN® - Sulfonated styrene-maleic anhydride copolymer based (SSMA for short), low molecular weight, high-performance thinner. Controls rheology at elevated temperatures. Water-soluble, easily dispersed.

• Thermal stability over 500°F (260°C)

• Deflocculates water-based systems at extreme downhole temperatures

• Helps minimize thermal flocculation

• Stabilizes the rheological and filtration properties of WBM at extreme temperature conditions

• Environmentally safe

Formate brines and supplemental thermal stabilizers are always used to help extend the thermal stability of AQUADRIL® polymer-based drilling fluids. Additionally, the system is stable in the presence of contamination from soluble calcium, salts and acid gases.

SHARK’s expert can customize the fluid with stable properties at temperature extremes for your most demanding downhole conditions. Deploy the AQUADRIL® water-based drilling fluid at temperatures greater than 450°F and in the presence of contaminants with densities exceeding 19ppg (2.3 sg).

The benefits of AQUADRIL® water-based system are summarized as:

• Higher technical level than traditional sulfonated high temperature system

• Long term stability of system by minimized gelation at max temperature & pressure

• Flexibility in brine selection, including potassium, sodium, calcium or formate-based

• Tolerance to contaminants, resistant to higher solids content and reservoir components - H2S, CO2

• Improved mud rheology with low colloidal solids content

• Low HPHT filtrate with thin filter cake

• Prevention of barite settlement

• Reuse of fluid to multiple wells or batch drilling wells

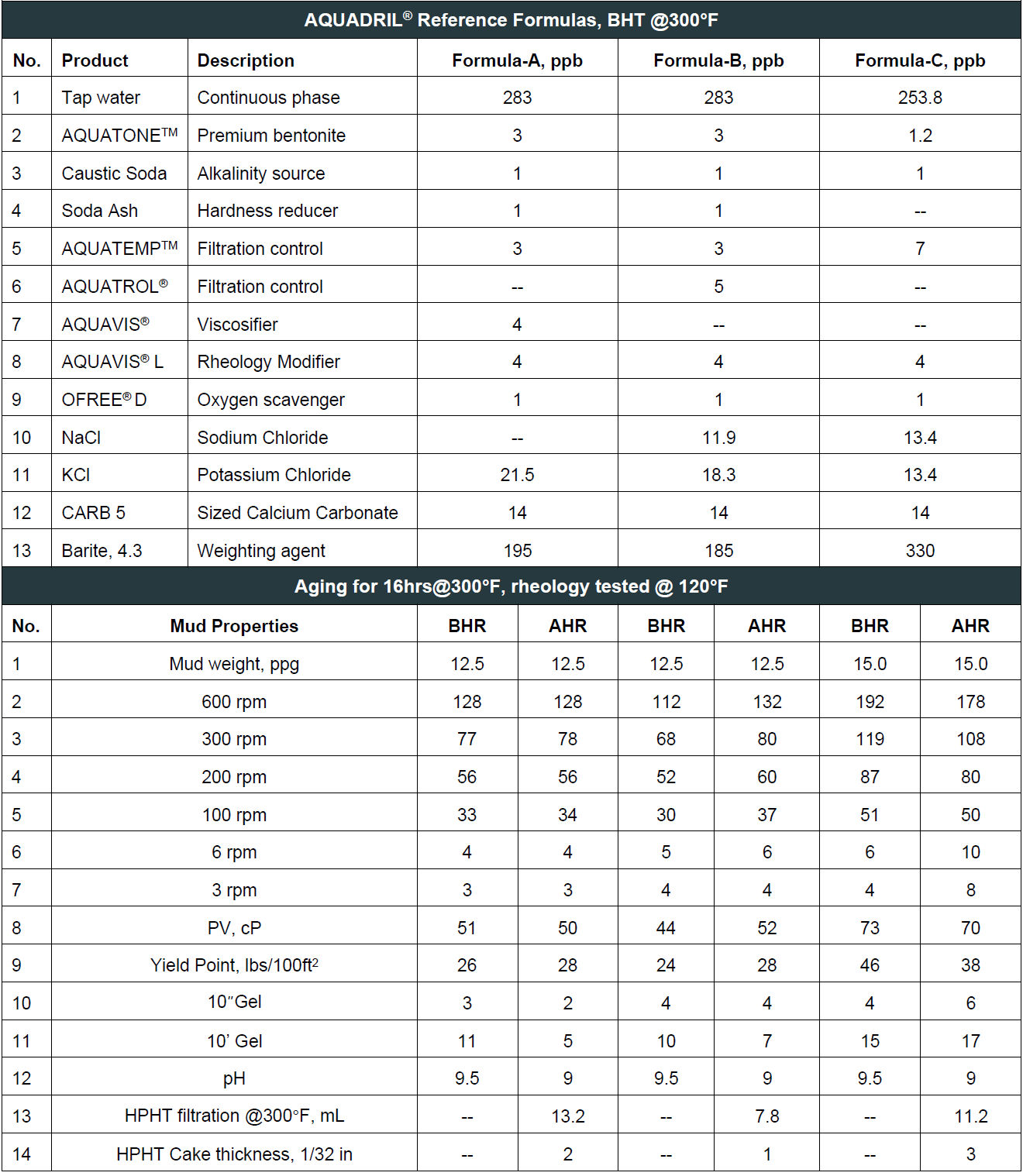

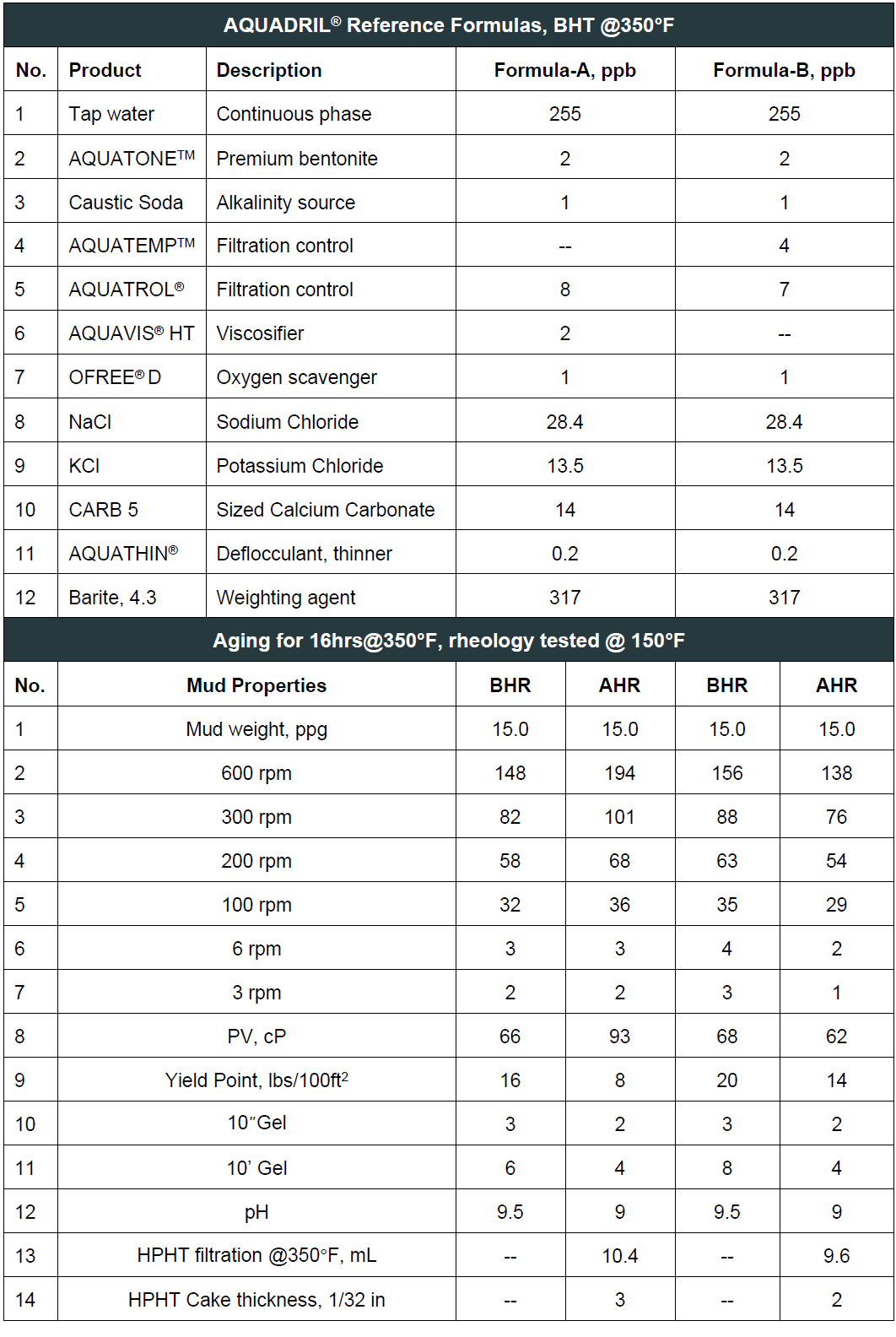

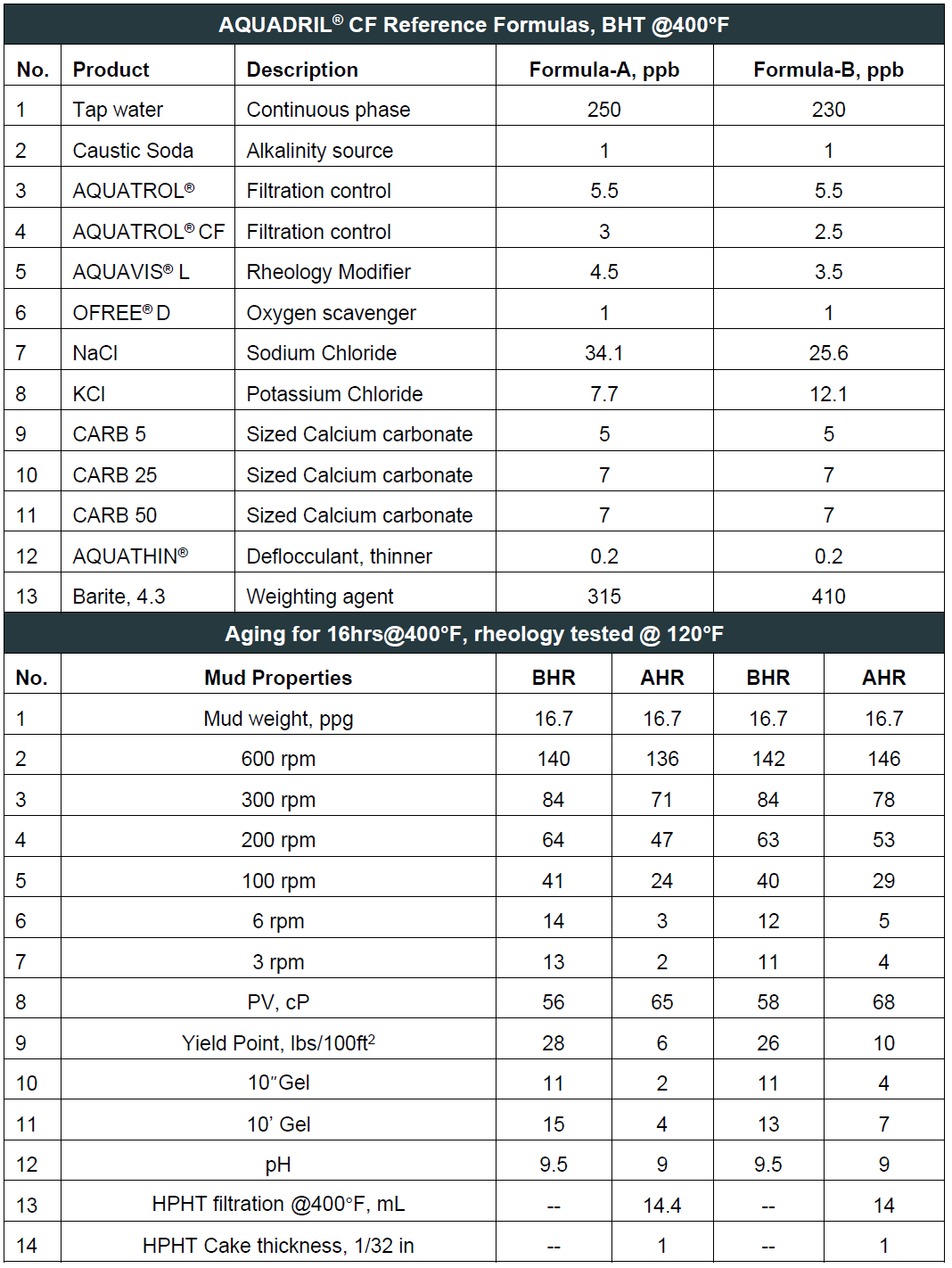

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

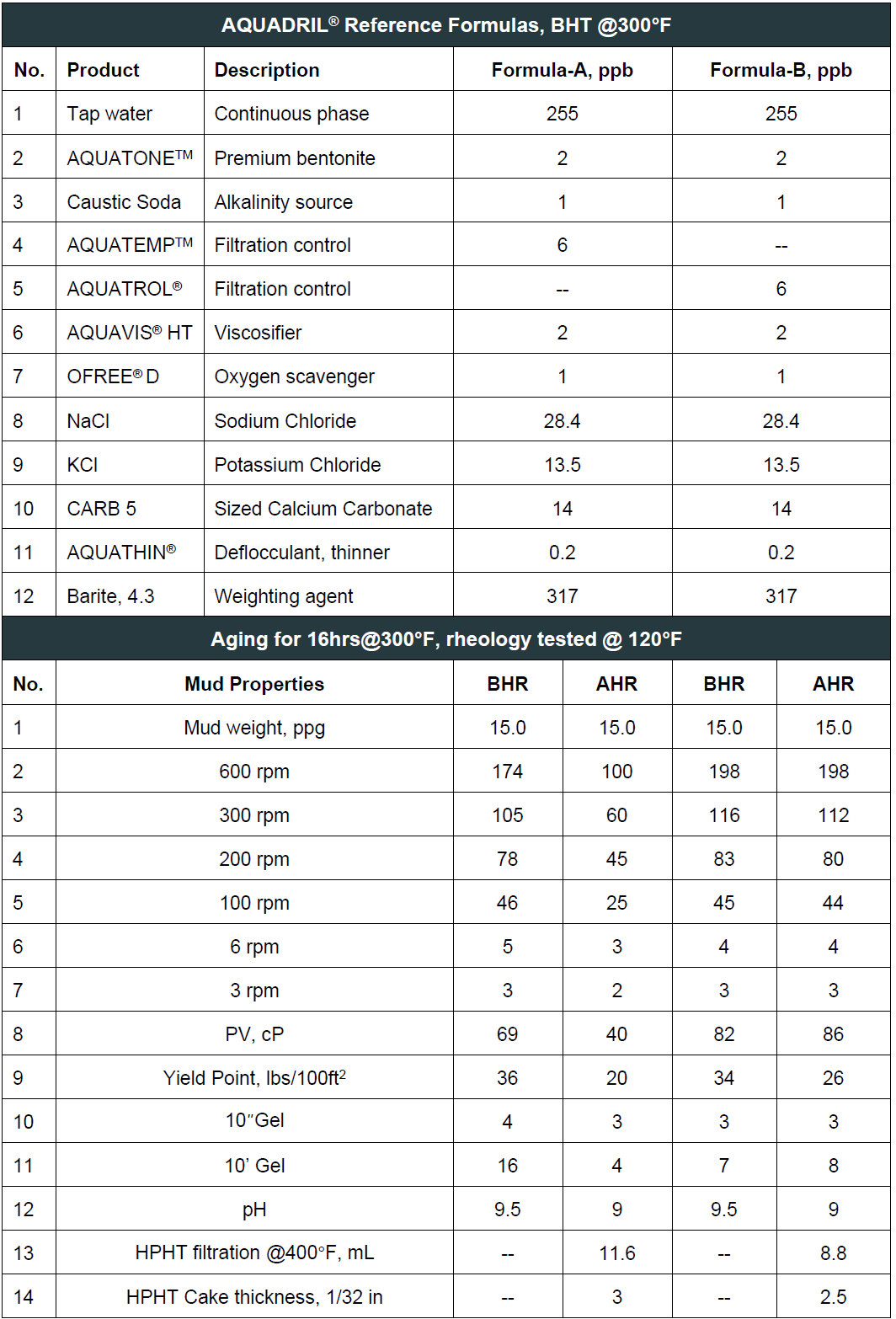

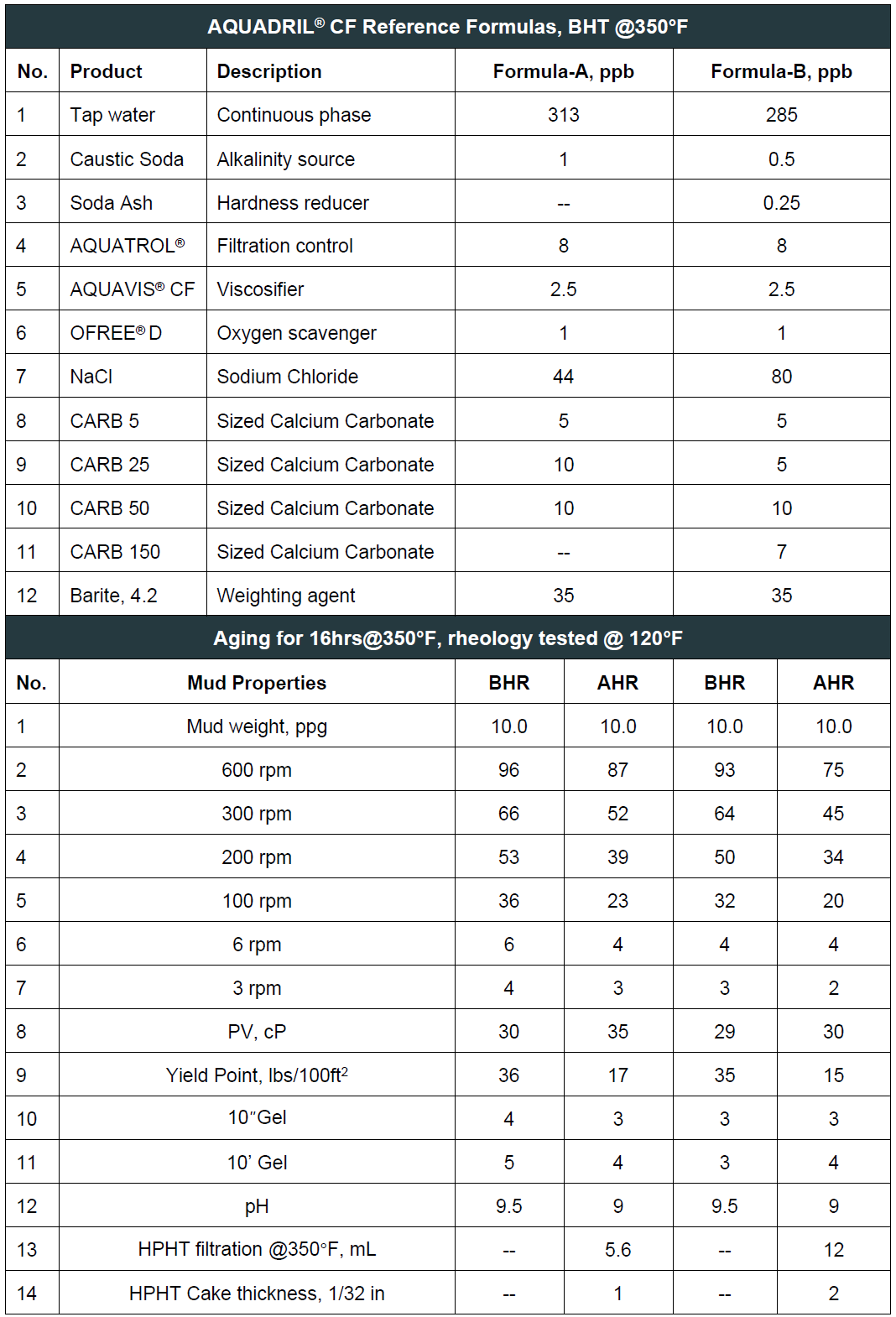

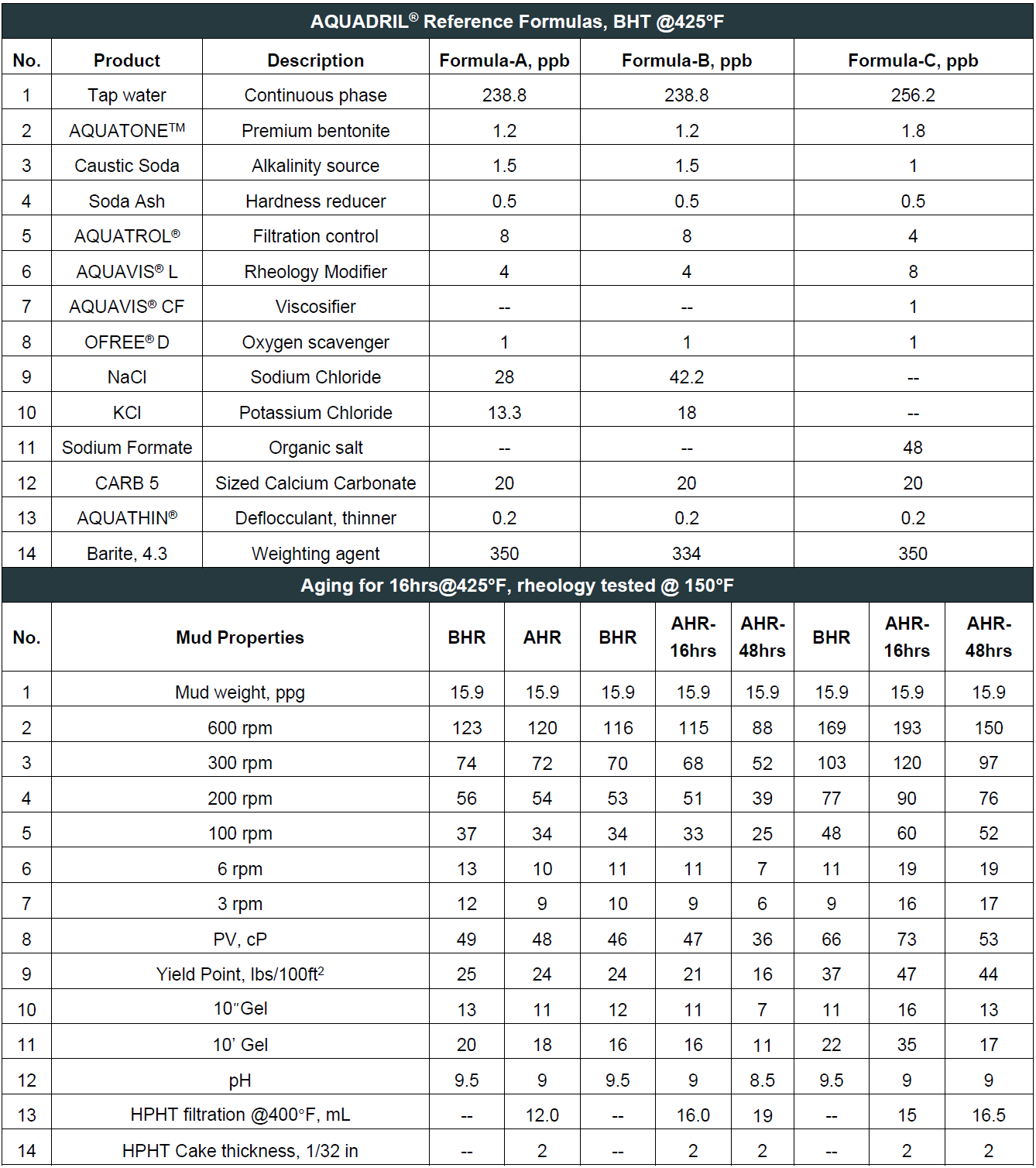

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

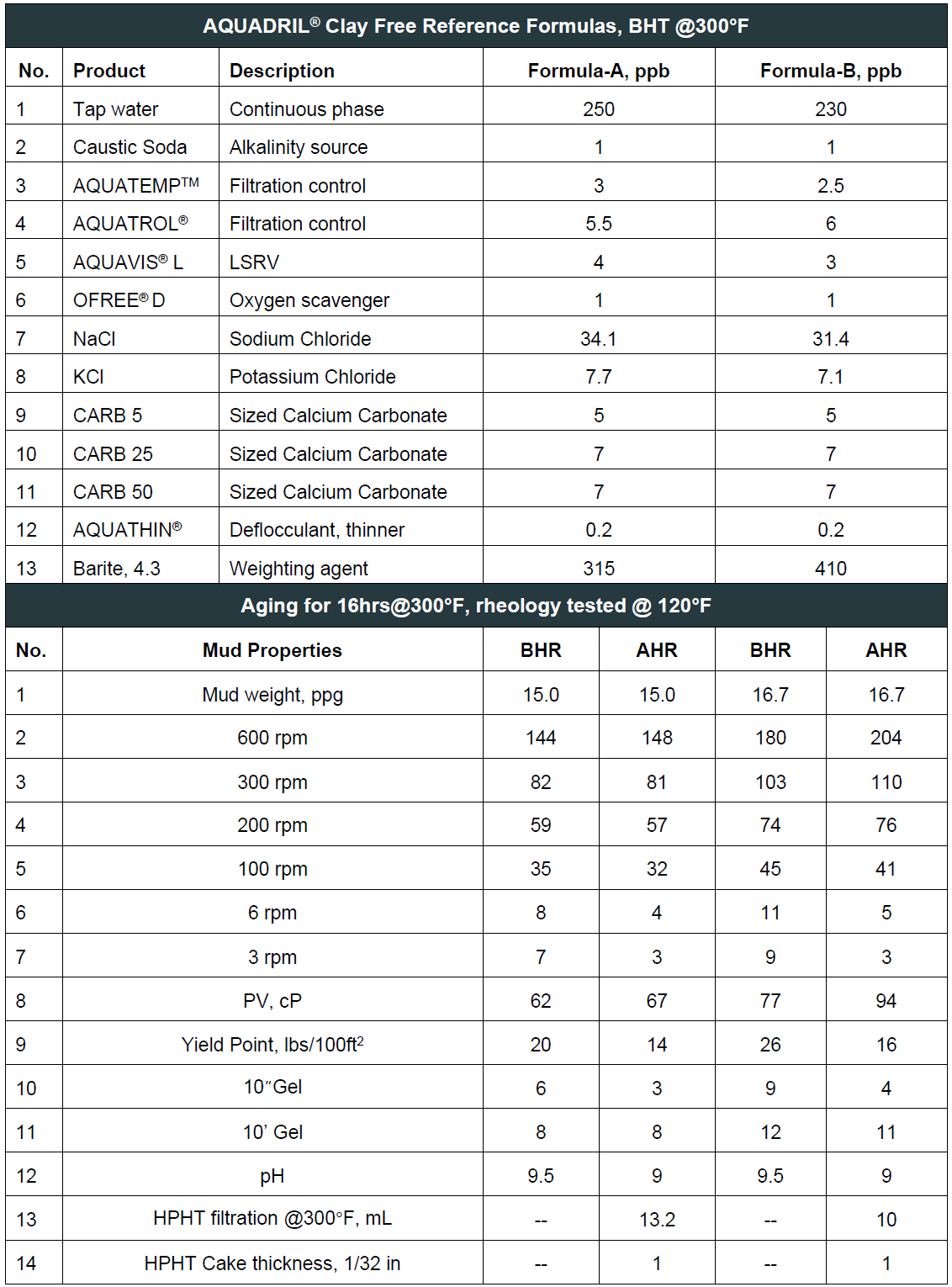

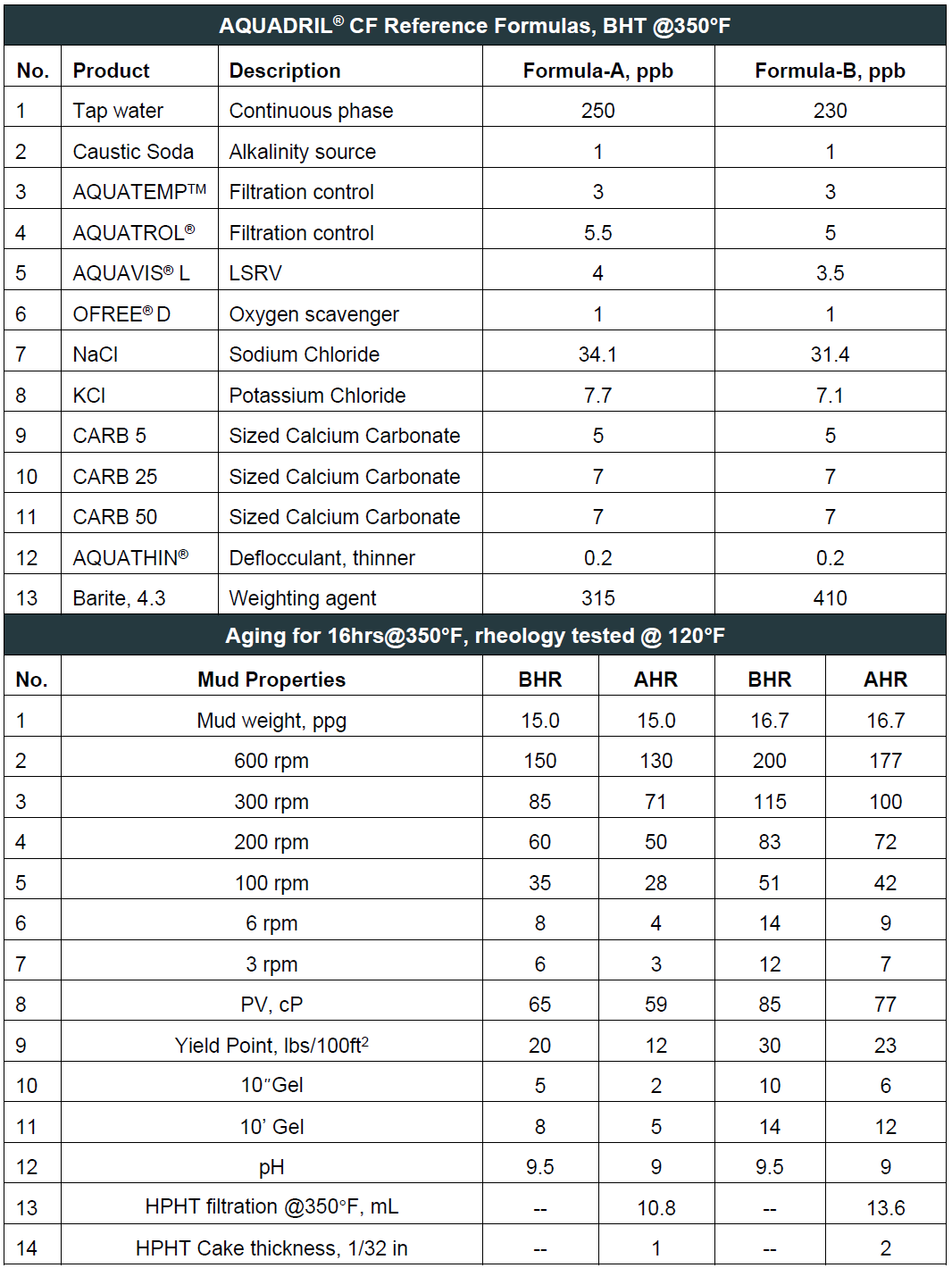

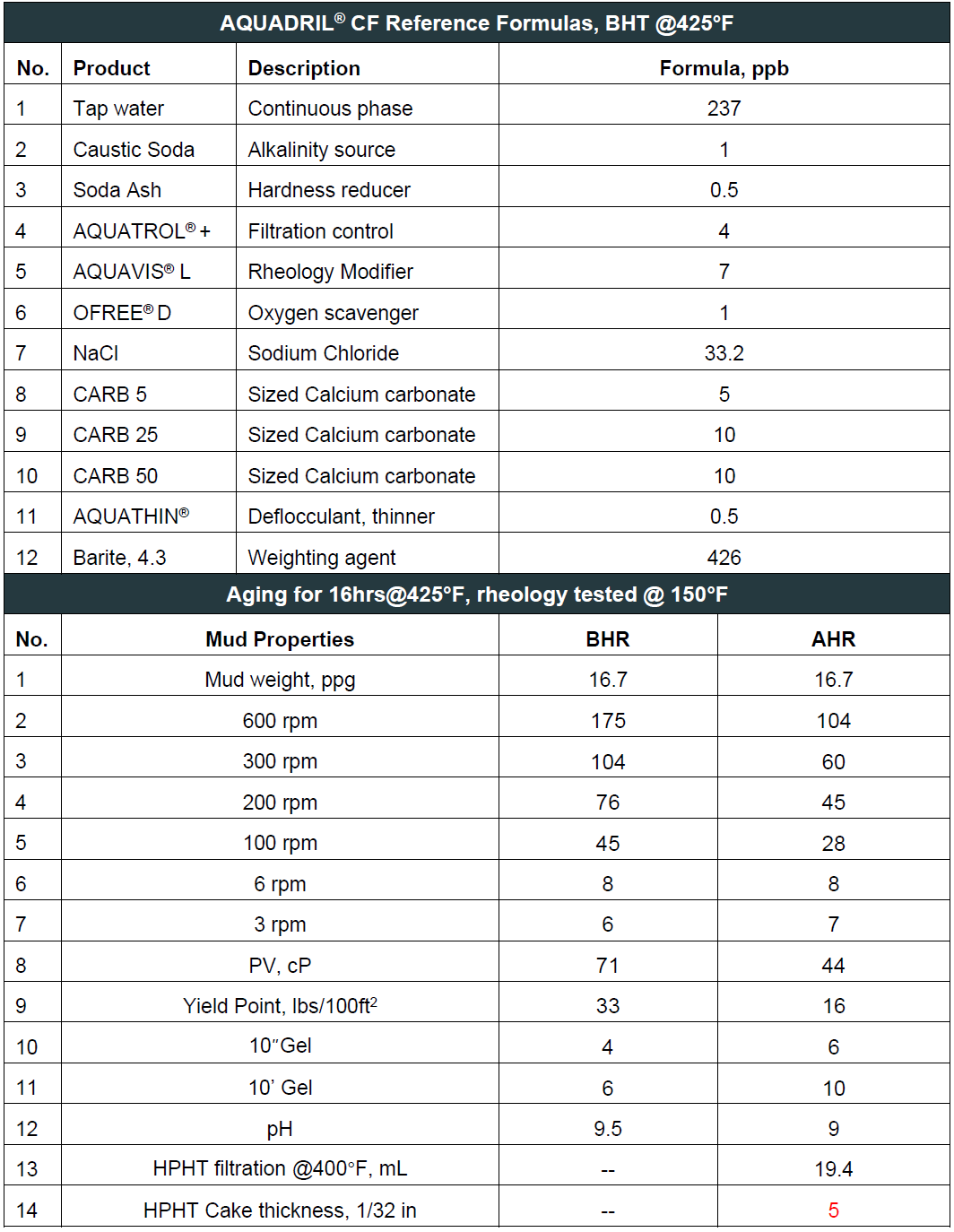

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

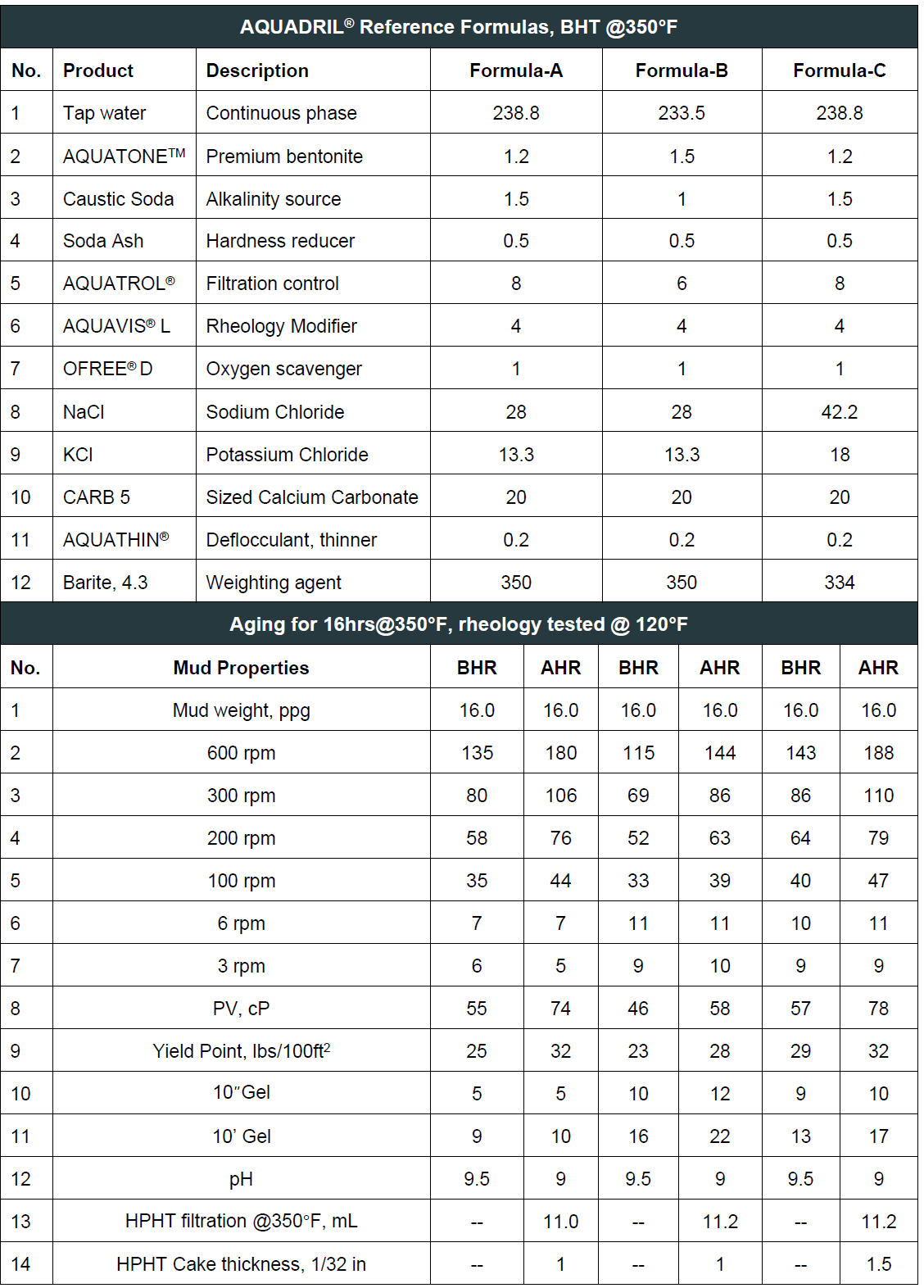

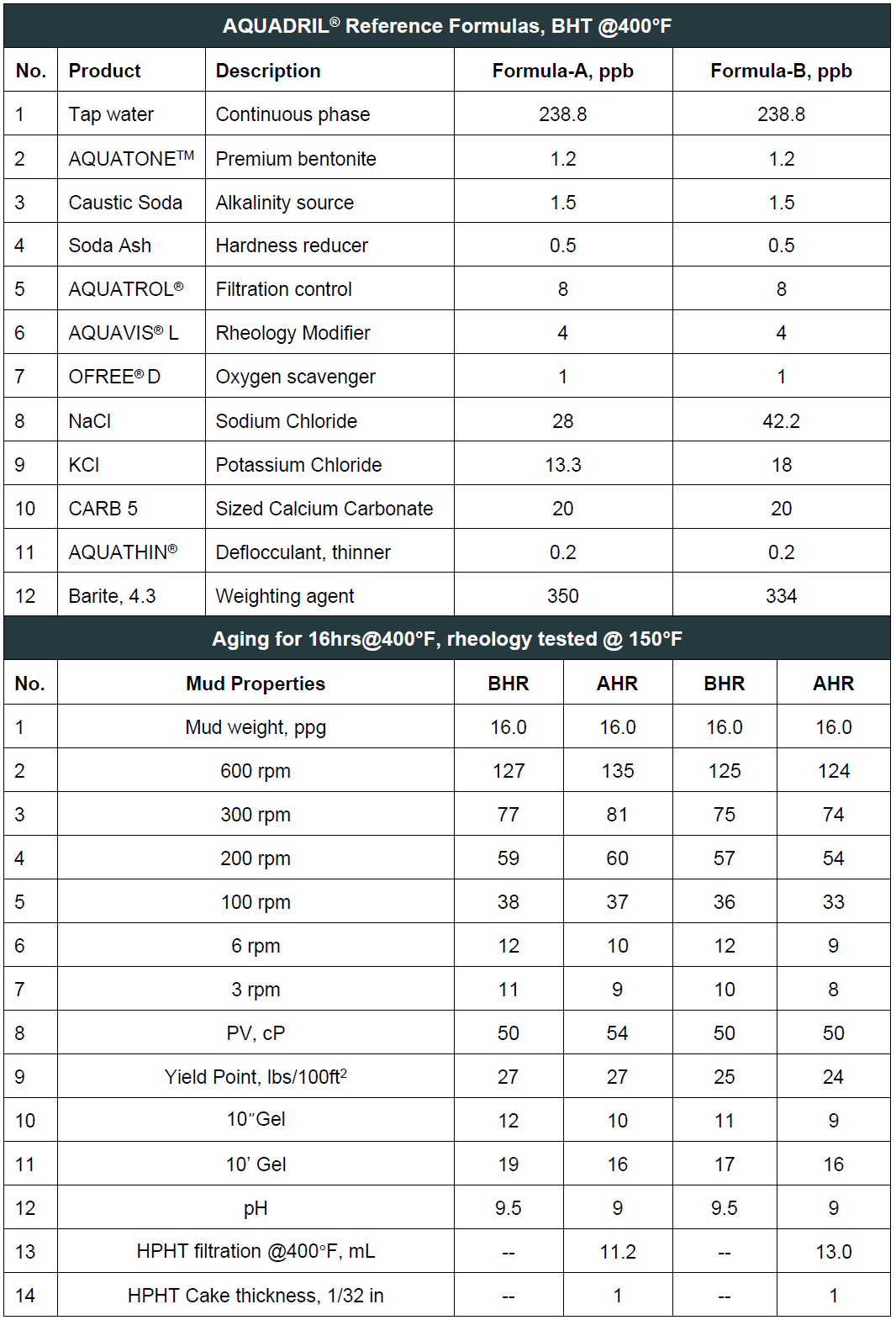

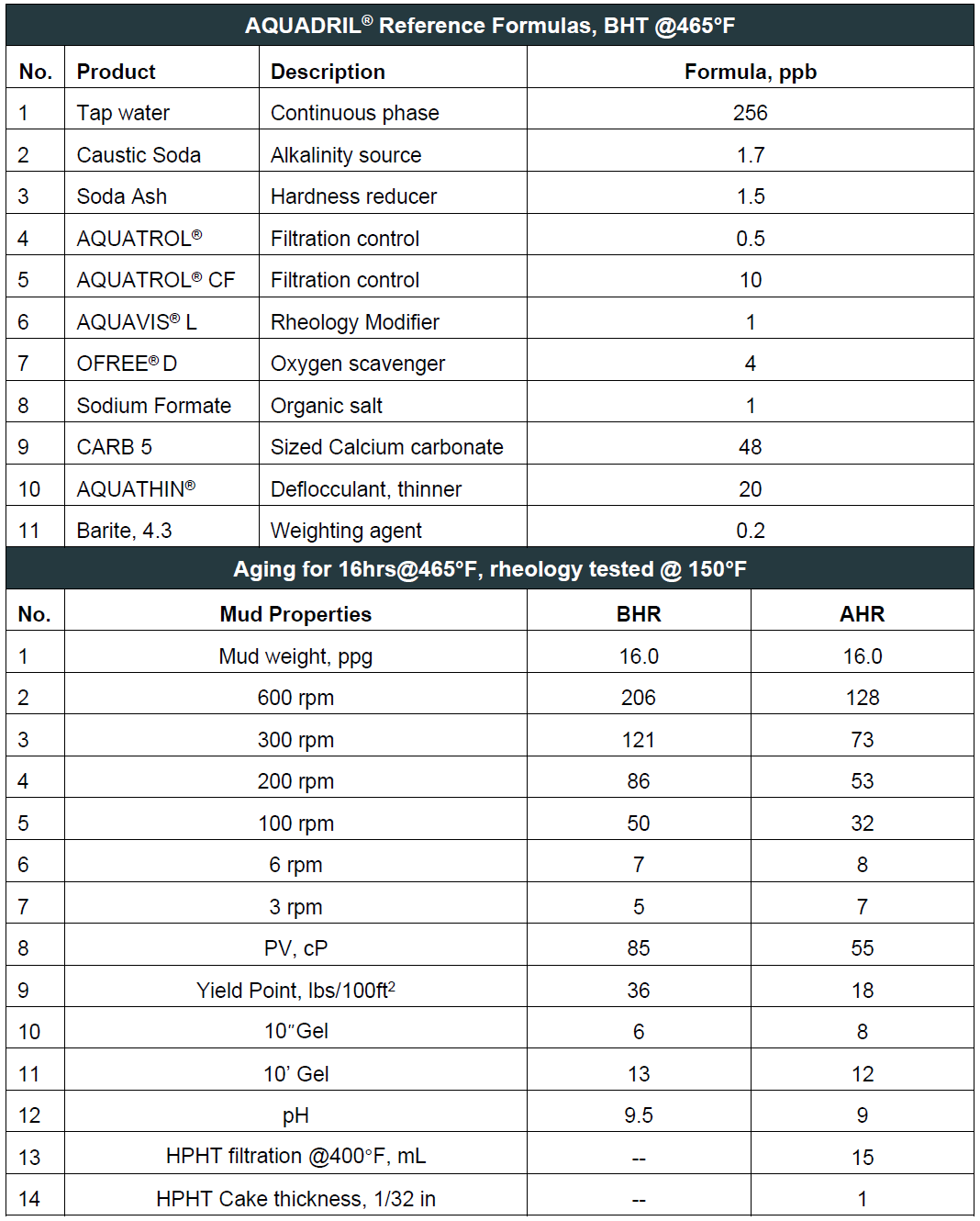

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Allow the bentonite to yield for at least 16 hours to achieve fully hydrated

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

To achieve a customized drilling fluids solution and optimized thermal stability, a suite of all items in water-based mud testing have to be conducted. Besides, special designed laboratory tests are also critical to the successful application of AQUADRIL® system in the field.

A properly equipped mud lab on the rig with a roller oven, aging cells, and rheometer cups will be essential. Pilot testing should be carried out to determine fluid stability and proper treatments, in anticipation of all upcoming operations such as trips, cement jobs, logging etc. when the fluid will be under worst case conditions. Samples of the drilling fluid should be routinely sent into the local labs for FANN 70 and FANN 90 testing as well as routine testing on the dynamic high angle sag tester - DHAST.